Robot is the core word of each of its achievements, accompanied by keywords such as “flexible”, “micro”, “medical” and “bionic”. Previously, he has developed representative achievements such as ultra-thin flexible climbing robots and bee flying machines.

Not long ago, Wang Hongqiang, currently an associate professor at Southern University of Science and Technology, developed a soft vine robot. Among them, a self-developed technology – soft demolding technology is used.

It has the advantages of simple processing process, easy availability of required materials, and no need for solvent participation, and has good universality. In the field of robotics engineering and biomedical engineering, such as miniature soft medical robots for interventional medicine, wearable sensors and antennas for health detection inside and outside the human body, and various microfluidic chips and organ chips, etc., have broad application prospects .

Plants and animals in nature are various and colorful, but they have a very important feature, that is, they all contain tiny channels in their body structures.

For example, the large and small blood vessels in the human body are essential organs for our survival. Similarly in plants, ducts are needed to transport nutrients.

Microchannels generally have the characteristics of complex shape and wide scale distribution, which are of great significance to the survival of many organisms.

In recent years, microchannels have gradually become the basic technology in many frontier fields. For example, micro-soft robots need micro-channels to distribute stress and strain to achieve deformation; the frontier of biological research – organ chips and micro-channel chips, etc., rely on micro-channels of different shapes and sizes for fluid manipulation; wearable devices In the field of flexible communication and other fields, microchannels also play an indispensable role.

However, under the existing technical conditions, it is difficult to fabricate micro-channel structures with complex structures. Therefore, in recent decades, this has been the focus and direction of many scientists in many fields.

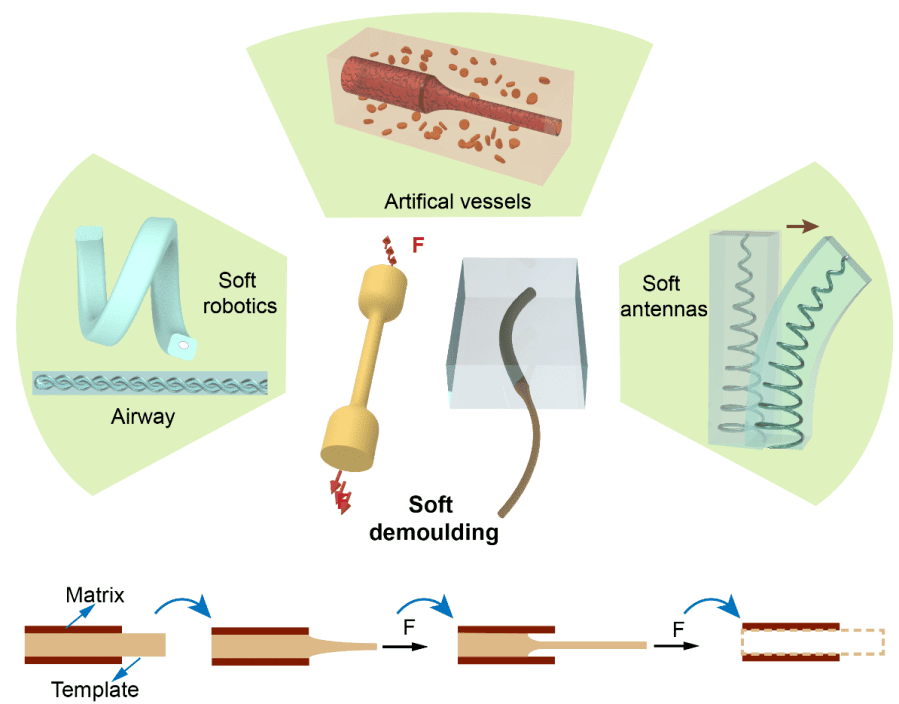

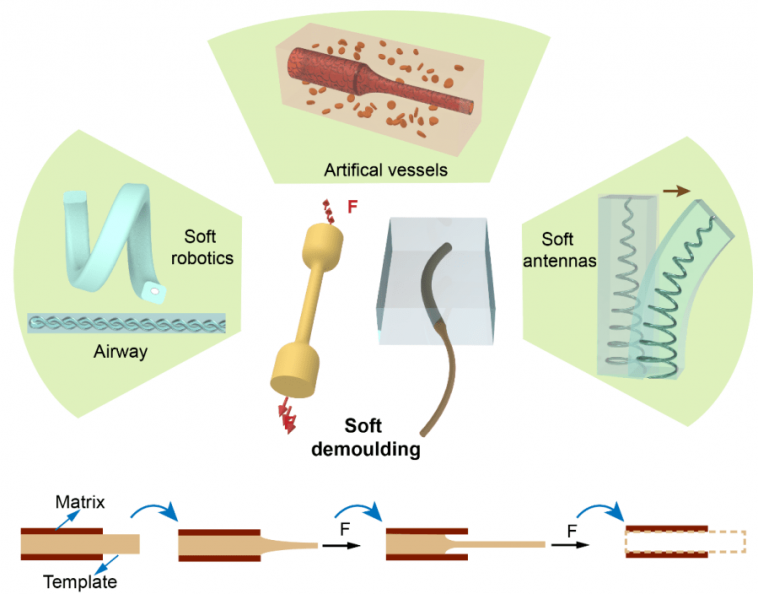

Figure | Conceptual image of soft demolding technology (Source: Nature Communications volume)

At present, researchers mainly use soft lithography technology to reproduce the micro-groove structure on the mold through liquid silica gel material, and then seal a layer of silica gel layer to form the channel structure.

However, the processing of soft lithography requires a clean room, complex process, and is only suitable for the preparation of two-dimensional square channels, and it is difficult to realize microchannels with different cross-sections and three-dimensional complex structures.

Therefore, in recent years, different microchannel processing techniques have emerged in the field, which are mainly divided into the following three categories: dissolution template method, matrix swelling method, and direct 3D printing method.

However, none of these three methods are perfect. Specifically:

The dissolving template method is time-consuming and only suitable for specific materials, such as acetone can only dissolve acrylonitrile butadiene styrene;

The matrix swelling method requires the participation of chemical reagents, such as acetone swelling polydimethylsiloxane (PDMS, polydimethylsiloxane), because there will be chemical reagent residues, so it is not suitable for biomedical fields such as organ chips, etc.;

Although the direct 3D printing method can print complex channels, it has the problems of poor scalability and low printing accuracy, and the rough surface will increase the resistance of fluid action and reduce the air pressure resistance of the software driver. functional requirements of the device.

Therefore, a novel microchannel fabrication process is urgently needed to realize the fabrication of smooth, complex, and high aspect ratio channel structures.

The direction favored by the world’s top journals

Inspired by the phenomenon that polymer fibers are necked under external force, the team innovatively proposed a simple, fast, solvent-free, and complex and high-aspect-ratio microchannel method—soft demolding technology ( soft demoulding).

Different from the traditional method of burying the hard formwork in the base material and then extracting it, it introduces a flexible soft formwork into the demolding process.

Under stress, the cross section of the soft formwork will become thinner, so that the demoulding process of the soft formwork becomes a peeling process that is no longer sensitive to the shape and length of the formwork, thereby greatly reducing the cost of removing the formwork. The external force required is suitable for a variety of soft matrix materials, and can be used to prepare complex, high aspect ratio microchannels, and has application potential in the fields of soft robots, wearable sensors, and organ chips.

Recently, a related paper was published in Nature Communications under the title “Self-shrinking soft demoulding for complex high-aspect-ratio microchannels”. Fan Dongliang, a doctoral student in Wang Hongqiang’s team, serves as the first author, and Wang Hongqiang and Qin Peiwu, a special researcher at Tsinghua-Berkeley Shenzhen Institute, serve as co-corresponding authors [1].

Figure | Related papers (Source: Nature Communications)

During the submission process, a reviewer said that the preparation technology is very innovative. Another reviewer pointed out that the soft demolding technique can produce fairly complex circular pipes with a length-to-diameter ratio far exceeding that of traditional fabrication processes, and it is expected that this work will attract scholars from different fields studying microfluidics. interest and attention.

In fact, in September 2021, the team submitted a paper to the main journal of Nature, but soon after the journal published a similar paper, the other party also proposed a method to prepare a tubular soft body structure, and applied the method to In the field of soft robots, and also made a soft vine robot similar to this paper.

The team said: “Maybe the themes are similar, so the editor of Nature did not send us for review, but the editor affirmed the innovativeness of our method and recommended submission to “Nature Communications”, and it can be directly submitted for review. We felt very sorry at the time, but at the same time I am also fortunate, because our chosen research direction is also favored by the world’s top journals.”

Taking snake molting as inspiration for research and development, more than 100 times of trial production for exploring and optimizing parameters

According to reports, it took more than three years from the initial idea of the researchers to the final publication of the paper. During the period, in order to explore the optimization parameters, the number of trial production exceeded 100 times, and it took about half a year to reply to the review.

The original idea for the project came from the needs of the research group and inspiration from nature. Flexible actuation is the main research direction of the team, where both flexible electrodes and pneumatic actuation require microchannels.

However, it is very difficult and limited to make the channel small, and it is even more difficult to make the shape and cross-section with space complexity, which made them very distressed.

Later, a video of snakes shedding skin brought inspiration: snakes gradually detached from their old shells by contracting their own muscles and rubbing on rough ground. Moreover, the shed snake skin can still maintain its original shape and fine scale features.

The rubber band also has a shrinking cross-section phenomenon under external force, so the research team considered burying the rubber band in the silicone material and then pulling it out, thereby imitating the process of snake shedding.

After confirming that the preliminary verification scheme is feasible, the team established a corresponding theoretical model for the soft demolding technology. During the establishment process, they made important distinctions between the model and soft demolding and hard demolding.

In the process of hard demoulding, the template is subjected to shear force, and the magnitude of the force will be affected by the length, and the greater the length, the greater the force.

In the process of soft demolding, the soft template will shrink and become thinner under the force, and then the shear force can be converted into peel force. During the period, it is not affected by the length and can be used to prepare microchannels with high aspect ratio.

And by testing four different materials (nylon wire, copper wire, hot melt adhesive fiber, polyurethane fiber), the correctness of the proposed model has also been verified.

After confirming the theoretical model, the research group carried out further research on the material selection and preparation process of the soft template. The rubber band was used before, and the contact part with the silicone material (PDMS) was not cured, which would affect the structural accuracy of the channel.

Moreover, commercially available rubber bands are only available in a fixed diameter, which severely limits the design of the formwork structure. Therefore, the researchers decided to use the thermal drawing method with simple equipment and controllable diameter through literature search and discussion to prepare the soft template structure.

Among them, hot melt adhesive and thermoplastic polyurethane are used as template materials, which have the advantages of low modulus and high elongation. Soft template structures such as conical, helical, double helical, tree-like, and saddle surface shapes were prepared by controlling the extraction rate, heating temperature, template post-processing, and mold assembly.

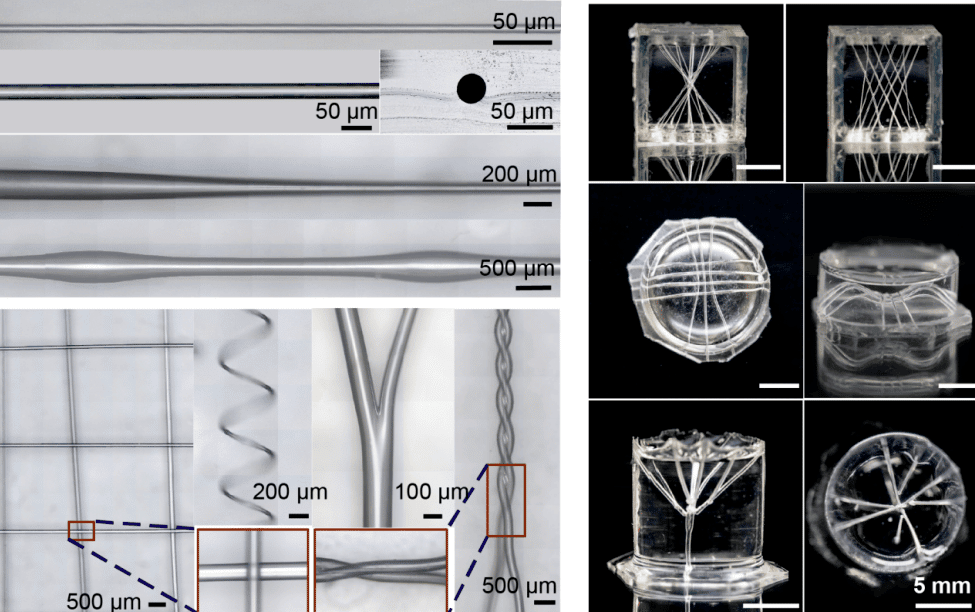

Based on the soft demolding technology, the above-prepared template structures can be processed into corresponding micro-pipe models through the soft demolding technology. Among them, using this soft demolding technique, the team produced micropipes with diameters as small as 10 microns and aspect ratios as high as 6000.

Figure | Various microchannel models prepared by soft demolding (Source: Nature Communications volume)

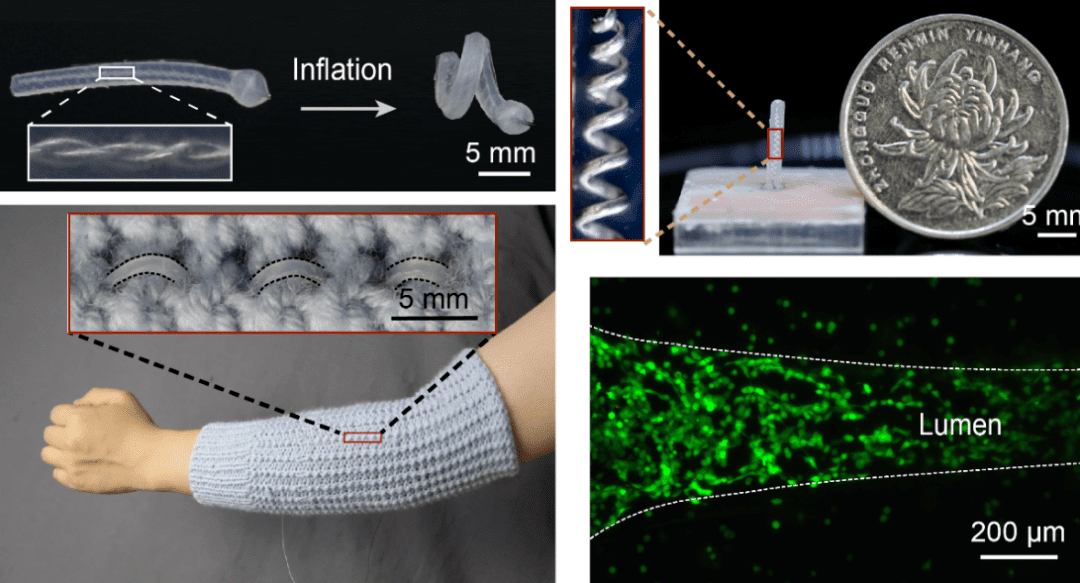

To demonstrate the broad application of soft demolding technology, the researchers first used the technology to fabricate tiny soft robots and wearable sensors. Through this technology, the research team fabricated a microchannel with a double helix structure and a diameter of 100 microns as a pneumatically driven channel, which can curl up like a bug when inflated.

Another air cavity with a diameter of 150 microns and an aspect ratio of 1600 has an ultra-long helical structure, which can imitate the curling behavior of vines when inflated, and can be used for medical treatment or detection in narrow scenes.

An elongated channel with a circular cross-section can be injected with conductive liquid to form a wearable sensor for human motion detection.

(Source: Nature Communications volume)

In addition, there is a channel with a variable-diameter three-dimensional helical structure, and by injecting liquid alloys, a microscopic soft antenna can be formed, which can be used for signal transmission in wearable devices.

In order to demonstrate the application of soft demolding technology in the field of biomedical engineering, the team cooperated with the research group of Associate Professor Qin Peiwu to apply soft demolding technology to the preparation of vascular models, and verified the negative effects of residual solvent on cell growth in vascular models. Prove that the technology has good biocompatibility.

In the future, the researchers plan to use new template materials, such as hydrogels with self-lubricating properties, ultra-high tensile strength, and new soft template processing techniques, to achieve more complex, personalized, and customized channel structures. preparation.

Moreover, it will also cooperate with scholars in different fields to apply the technology to more specific scenarios, such as wearable sensors for motion detection and soft robots.

GIPHY App Key not set. Please check settings