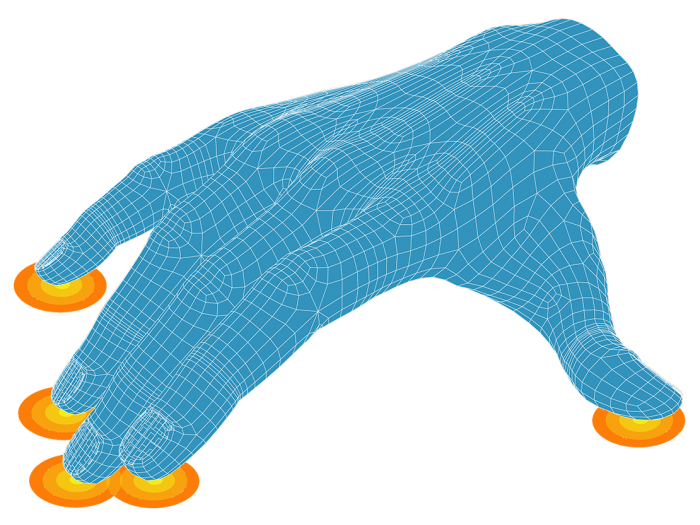

Robotic tactile sensors can help a robot measure any physical interaction with its environment, which is capable of measuring parameters related to the sensor’s contact with an object. Also benefit from haptics. Force and tactile sensors enable robots to manipulate objects with greater precision and sensitivity in less structured environments.

What is a tactile tactile sensor?

Tactile sensors are designed based on the biological sense of their touch and are able to detect stimuli from mechanical stimuli, temperature and pain. A tactile sensor will receive and respond to a signal, which can be force or physical contact. Tactile sensors are sensors used in robotics to mimic tactile functions. According to the function, it can be divided into touch sensor, force-torque sensor, pressure sensor and sliding sensor.

What are tactile sensors?

1. Optical tactile sensors: There are two types of optical tactile sensors, intrinsic and extrinsic, in which the intensity of light is modulated by moving obstacles into the light path. It has advantages such as immunity to electromagnetic interference, and has a very high resolution. Low wiring is required and processing electronics can be kept away from the sensor.

2. Piezoelectric tactile sensor: The effect of generating a voltage on the sensing element when pressure is applied to the sensing element is the piezoelectric effect. The generation of voltage is proportional to the applied pressure. In this case, no external sensor is required. The advantages of this type of sensor are durability and wide dynamic range. Pressure measurements can be made.

3. Resistive tactile sensor: The work of this sensor is based on the resistance change between the conducting polymer and the electrode. This type of tactile sensor is widely used. When pressure is applied, the electrical resistance of the conductive material changes. Then measure the resistance. The advantages of this sensor are high durability and good overload tolerance.

4. Capacitive tactile sensors: In capacitive sensors, the change in capacitance between two electrodes is used. This type of capacitive sensor will measure capacitance, which changes under applied pressure. The capacitance of a parallel plate capacitor is related to the spacing of the plates and their area. Capacitance will vary depending on the load. The advantages of this sensor are linear response and wide dynamic range.

5. Magnetic tactile sensor: Magnetic tactile sensor uses two methods, one is to measure the change of magnetic flux density using a magnetoresistive device, and the other is to change the magnetic coupling deformation between the windings of the magneto-elastic core. The advantages of this sensor are high sensitivity and no mechanical hysteresis.

The role of robotic tactile sensors

In industrial robotic manipulation technology, as in the human domain, vision and touch are complementary modalities. Industry experts predict that touch sensing will soon add vision to mainstream robotics applications. Basically, a robotic tactile sensor is a touch sensor that provides information about objects it comes into contact with. The information conveyed is about the shape, size and type of the touched object.

Robotic tactile sensors are able to detect certain things, such as the presence of an object. It can also determine the shape, position and orientation of the part. The object in contact with the sensor, the contact is the pressure, so the pressure distribution can be determined. Inspection of objects such as texture monitoring, joint inspection or damage detection can be done with this device. Industrial robotic tactile sensors are capable of detecting various stimuli, it can detect the presence of objects, and it can also acquire tactile images. A tactile sensor has many sensitive parts, and with the help of these parts, a tactile sensor can measure several properties.

The robotic tactile sensor functional assembly includes a microswitch, which is a switch that is sensitive to different ranges of motion. It’s an array of touch sensors that make up a larger sensor called a tactile sensor. A separate touch sensor will account for the physical contact between the robot’s fingers and the textured surface. Once the robot makes contact with the item, a signal is sent to the controller.

GIPHY App Key not set. Please check settings